Tianjin Xuansheng Technology Co.,Ltd.

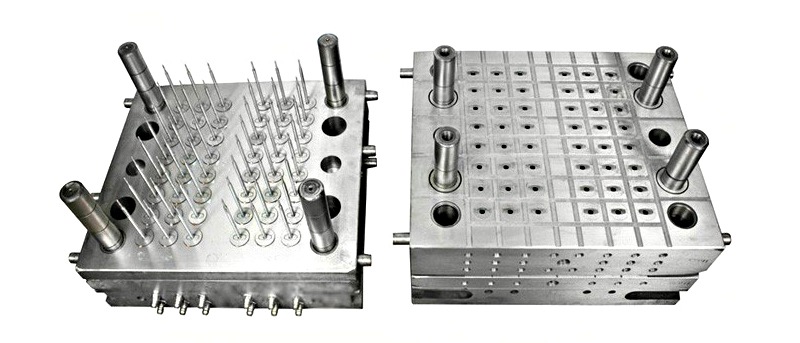

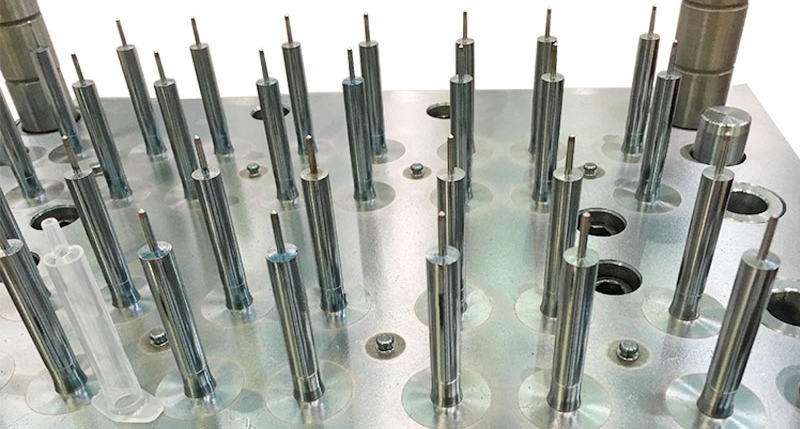

Syringe thin wall injection molding medical product molds are multi cavity mold, from 8 cavity to 128 cavity, high precision and very good eccentricity ratio. Syringe Mould consist by barrel mold, plunger mold, and other molds as per requirement. We could provide syringe mold from 1ml to 100ml.

Syringe thin wall injection molding medical product molds are multi cavity mold, from 8 cavity to 128 cavity, hot runner system or semi-hot runner system, high precision and very good eccentricity ratio. Syringe Mould consist by barrel mold, plunger mold, and other molds as per requirement. We could provide syringe mold from 1ml to 100ml.

Technology Terms:

|

Mould working life:

|

1000K Shot time |

| Mold Core Steel |

H13, S136, SKD61, 1.2344, 1.2343 etc. as per order. Normally we make the mold by 1.2344 mold steel. |

| Runner |

Hot Runner / Cold Runner /Semi-runner as per order Full hot runner: Husky hot runner system Semi hot runner: Yudo |

| Syringe mold precision control |

0.02mm or as per required |

| Certificate |

ISO 9001, ISO13485 |

Business Terms:

1. Please share us your detail CAD or 3D drawing, or samples, we could customize as per your requirement.

2. All products will produce and delivered under the approved drawings by clients.

3. We keep confidential the product information of our customers.

4. The intellectual property rights of product belongs to client and have no relationship with us.

5. Trade Terms: EXW, FOB, CIF or required.

6. Payment terms: 50% remittance by T/T in advance, balance 50% before shipment.

7. T0 time: From deposit arrived in our account, to clients to confirm the drawn design.

8. T1 time: After customer confirmed 3D mold drawing, till we arrange courier samples to clients for confirmation.