Tianjin Xuansheng Technology Co.,Ltd.

1. What's the Insert injection molding

Insert Molding is a very widely used process. We are familiar with the technical details of the Insert Molding.

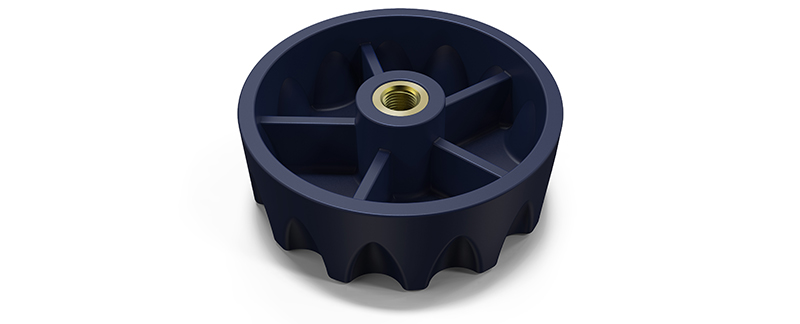

Molding metal and plastic together into a molded part, or molding multiple metals or materials together into a molded part. We sometimes call metal insert molding or metal screw/brass insert molding,

2. Insert Injection Molding Applications

The insert molding process can be used for the production of Integrated products, Auto industry, Medical industry, instruments, devices, knobs, electrical components, toy industry, home appliance industry, cookware, household equipment etc.

3. Insert Injection Molding advantage

Insert molding not only reduces assembly and labor costs, but is better than assembled parts, reduces the size and weight of the parts, improves the reliability of the parts, and provides improved part strength and structure through enhanced design flexibility.

1. Insert injection molding could simplify the process of the molding.

2. It will save the products processing time and the labor cost of processing.

3. The final product quality could be guaranteed, no need the rework production, and save the processing cost.

4. How to improve the bonding strength of insert parts

Reduce the influence of the external environment include:

1. We should pay attention to control mold temperature and humidity in the production environment.

2. Consider whether metal inserts need to be warmed up and dry.

5. How Integrated products insert Molding

1. The insert molding process takes advantage of the insulation of plastic materials and the electrical conductivity of metals, it's widely application in the electrical products molding.

2. The finished products after insert molding can meet the basic functions of electrical products: conductivity and insulation.

3. The insert molding process can be used for the production of integrated products.

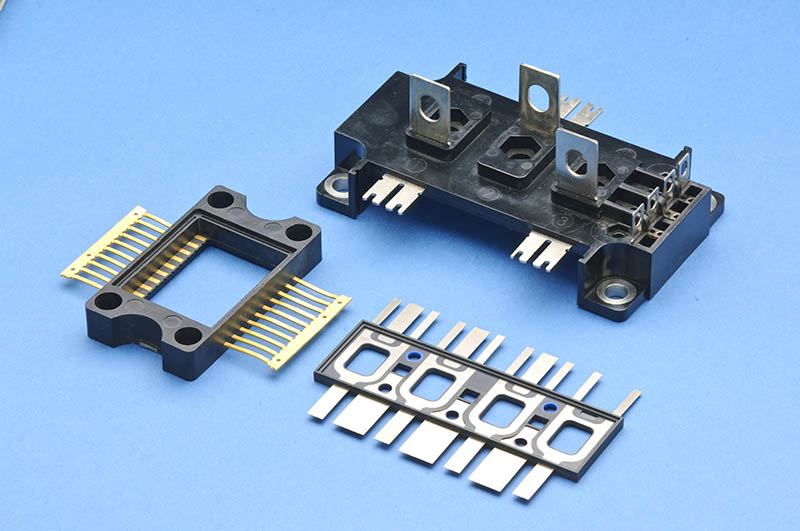

6. How electrical connection contacts insert molding

1. The metal inserts position accuracy is required to be higher.

2. Normally adopt the secondary injection molding process:

1) The first injection molding mainly supported and fixed the metal line very well.

2) The second time molding is used to the whole product finished.

7. Special attention for Insert Injection Molding

The special considerations for Insert Injection Molding as follows:

(1) Insert Molds design: Good insert mold design are very necessary before the insert and component molding, in order to avoid problems at the later stage.

(2) Enough material: Insert need enough plastic materials to support, to avoid the insert to fall away from the rest of the part. Have to make sure that there is enough plastic material to properly place the inserts before molding.

(3) Insert Pressure: Pressure is also a very important factor for insert molding, because during molding process will create a lot of pressure, Make sure the inserts withstand the pressure without cracking or deforming.

(4) Insert temperature:

During the injection molding process, the temperature needs to be controlled at the melt the injection material completely and without deforming the insert.