Tianjin Xuansheng Technology Co.,Ltd.

We are profession plastic injection mold manufacturer, 30 years experience technology team, Best quality mold start from Products design and mold Design & optimization. SOP As follows:

1. Products 3D scan processing

Some clients only have CAD drawings, not have 3D drawings. After estimate the quote and sign the contracts, Before mold design, we will 3D scan the samples which clients provided, and make the products 3D drawings confirmed the products structruer with clients first. If no need adjustment, we will go to next step: DFM report.

2. DFM REPORT

"DFM report" will study and check the product and mold details, we will optimize product designs, mold designs, and will avoid injection mold processing amendment after machinning process, improve T1 time and mold quality. DFM include:

1) Basic information of mold

2) Mold structure

(1) Gate type/location

(2) Mold ranking

(3) Clamping force

(4) Parting line

(5) Ejection method and position

(6) The main structure of the mold

3) Product analysis

(1) Product structure analysis

(2) Draft analysis

(3) Thickness analysis

(4) Surface requirements

(5) Date insert

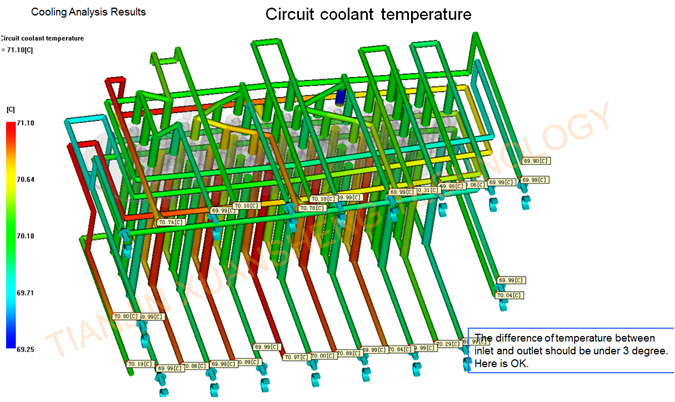

(6) Cooling water circuit

(7) Manipulator

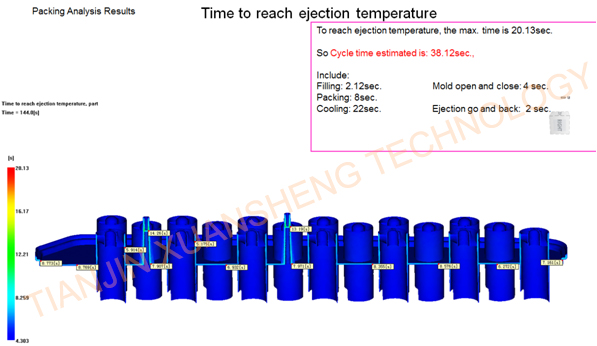

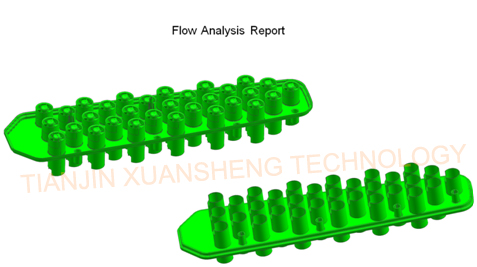

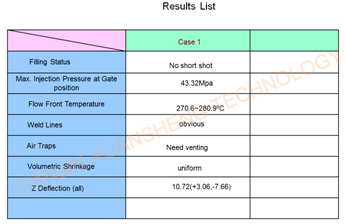

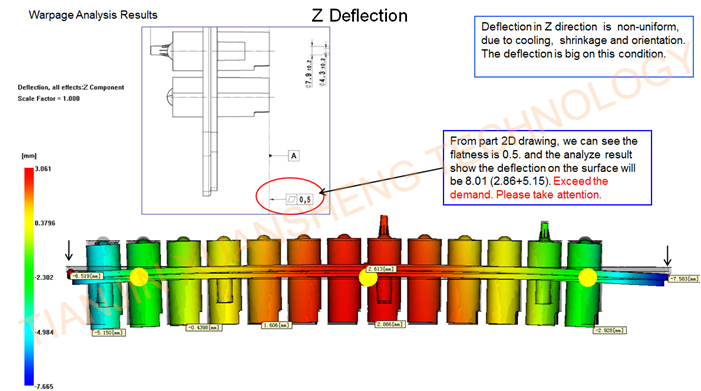

4) Moldflow analysis

(1) Wall thickness

(2) Runner system

(3) The location of Nozzle

(4) Plastic materials

(5) Filling condition

(6) Filling and Packing curve

(7) Filling time - Contour

(8) filling time - Animation

(9) Temperature at the flow front

(10)Pressure at V/P switchover

(11)Pressure at injection location

(12)Clamp force: XY Plot

(13)Weld lines

(14)Air traps

(15)Sink mark estimate

(16)Volumetric Shrinkage

(17)Deflection, all effects: Deflection

(18)Deflection, all effects: X Y Z Component

(19) Conclusions and suggestions

|

|

|

|

|

|

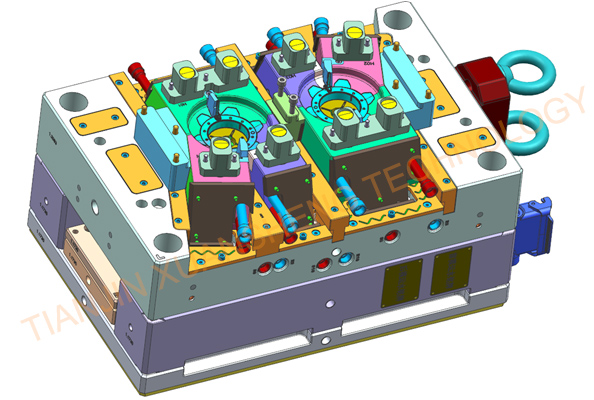

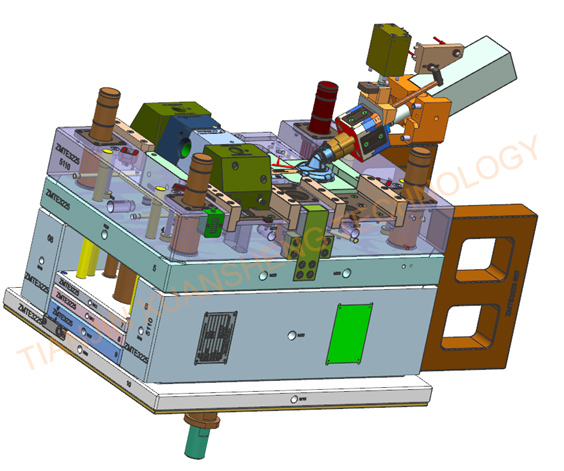

3. 3D Mold Design & Optimization

After DFM report finished, we will hold the kick-off meeting by designer, manufacture department director, QC department director, sales, and other necessary person, study all the points of the mold which have to pay attation to. Avoid problems in advance, Optimization the mold structure, make the injection moldiing more easy and stabilization, improve cycle time and technology, do best T1 molding could be successed, Save clients time.

|

|

|

|

4. 3D mold drawing confrimed by clients.

After 3D mold drawing finished, we will email 3D mold drawing to clients confirmation. After drawing be approved, we will arrange BOM and programming ASAP.