Tianjin Xuansheng Technology Co.,Ltd.

● Has a database of more than 8,000 plastic materials

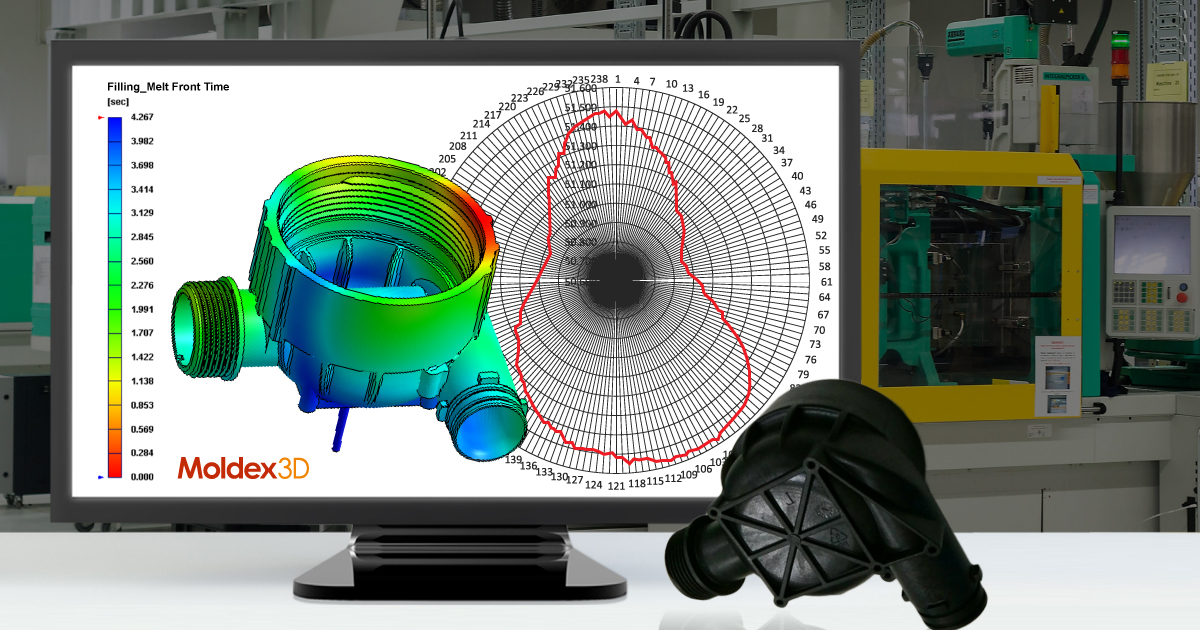

● Mold design is leading-in into molding simulaition analysis to predict molding difficulties and defects, and design optimization analysis is carried out until the best solution is obtained..

● The computer conducts virtual trial molds to test different products, gates, runners, waterways, etc., as well as the setting of plastic and molding conditions...

● Reduce the risk in product development, optimize the product structure, shorten the product development cycle, and succeed in T0...

● The injection molding data management platform records the design and mold trial to complete the development process, integrates all data into a big database, and visualizes the data (mold size, on-site mold trial parameters, DFM report, part quality inspection, mold trial report, CAE mold Analysis Results...)