Tianjin Xuansheng Technology Co.,Ltd.

Tianjin Xuansheng Technology, Your injection molding professional & reliable partner.

1. What' s is 2K molding?

2K injection molding process is mainly used in double injection molding with 2 different plastic materials or 2 colours, Some of the two materials are different colors, some are different soft and hard, so as to improve the product's aesthetics and assembly performance.

With the 2K technique a possible assembly step is prevented. The choice for a 2K or 2-component injection moulding process is primarily based on a cost advantages, design features or aesthetic preferences.

2. The advantage of 2K molding process:

1. Lower unit cost

2. Improved part integrity

3. Multi-material efficiency

4. Higher-quality plastic part fabrication

5. Beautiful Appearance and little fit up gap,

6. User-compliant and tailor made products.

7. Reduced handling and secondary assembly

8. Reduces cost and waste associated with assembly defects

3. What are the disadvantages of 2K injection molding?

Although there are many advantage for 2k molding, there are still some disadvantages for 2k injection:

1. 2k molding investment is large:

Compared with the single-stage injection molding process, the one-time investment cost of 2k injection molding is more expensive.

However, these costs will be recovered quickly in most cases because assembly steps and manual labor can be eliminated.

2. Plastic materials limited:

Not all plastic combinations are possible because some plastics do not adhere sufficiently to each other.

4. Why choose Xuansheng Technology 2k molding processes?

1. We are reliable partner:

We are happy to calculate for you whether 2k injection molding is suitable for you, or whether other injection molding options are more suitable for your product.

2. We are professional Molding Expert

As a strong 2K injection molding partner, we are happy to advise you on selecting the right material and determining the best processing method to optimize your products scheme.

We ensure that the final product fully meets or exceeds your expectations.

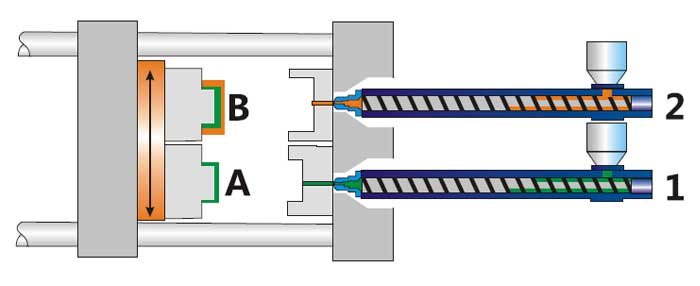

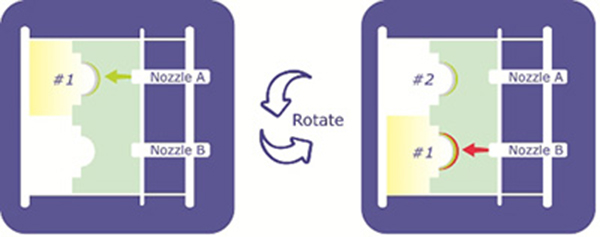

5. What is the working principle of 2K injection molding?

We build molds with 2 product cavities for this type of injection moulding. During the production process we inject plastic into one cavity of the mould. Once that has hardened, the mould rotates and we inject plastic into the other cavity, against the product that was formed in the first cavity.

6. What are the applications of 2K injection molding?

The 2K injection molding process is mainly used for products that need to meet certain special functions or appearance requirements. For example, some products need to be waterproof, drop-proof, and dust-proof, some products need a variety of colors on the surface to meet aesthetic requirements, and some products need good grip and touch. They all need to use two or more materials in one product, and they need to use 2K injection molding.

At present, two-color injection molding has been widely used in electronic products, power tools, medical products, home appliances, toys and other fields.